Real-World

Safety Stock Optimization

That Works

CHALLENGE

Does Safety Stock serve you well?

-

Does it help you eliminate overstock or stockouts?

-

Do safety stock formulas let you meet fill-rate target?

-

Do they reflect your actual demand patterns?

-

Are lead time and planning cycle truly in sync?

-

Do the formulas account for all your replenishment parameters?

SOLUTION

Data-driven simulation* methodology

-

Assures optimal cost/service balance

-

Delivers 98% confidence in achieving fill-rate targets

-

Accurately models real-world inventory behaviour

-

Reflects actual demand patterns

-

Includes all replenishment parameters

-

Explores and tests alternative scenarios

DELIVERABLES

Results within days -- no lengthy setup is required

-

Tailored inventory policy and safety stock levels

-

Confidence-based service level projections

-

What-if scenarios results

-

KPIs: inventory levels, replenishment stats, lead-time performance, etc.

INTERESTED?

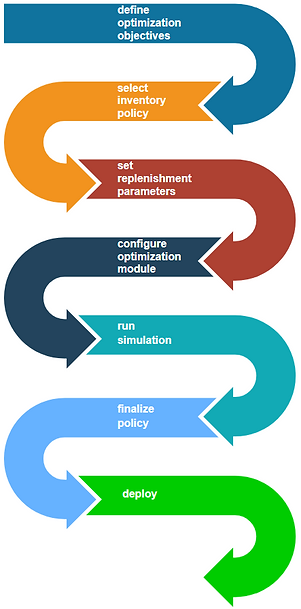

Way forward

-

You submit historical demand, supply data and key parameters

-

I run a simulation and deliver a tailored safety stock evaluation

-

We launch a pilot and implement the results into the ERP system

-

You monitor performance and key parameter behavior

-

I re-run the model and provide updated recommendations

* Monte Carlo simulation

Monte Carlo simulation is a technique used to assess the impact of uncertainty and variability in complex systems.

By running numerous simulations with random inputs based on defined probability distributions and other parameters, it estimates the range and likelihood of possible outcomes.

This approach supports data-driven decision-making under uncertainty.